With customers always pushing for cost reductions, saving money has become an overriding concern in all product specification. In the selection of an IP rated enclosure to use on the factory floor, there are five issues to consider insuring that you choose the most effective, but economical solution for your application.

1. Do you need your enclosure to be IP rated at all?

With factory floors increasingly clean, the need to protect sensitive equipment from dirt, dust, and liquids is significantly reduced. By specifying a traditional enclosure instead of an IP rated enclosure, the savings can be as much as 50-75%. Often, typical enclosure protection of sides, top and bottom enclosure can provide enough protection at a very inexpensive price.

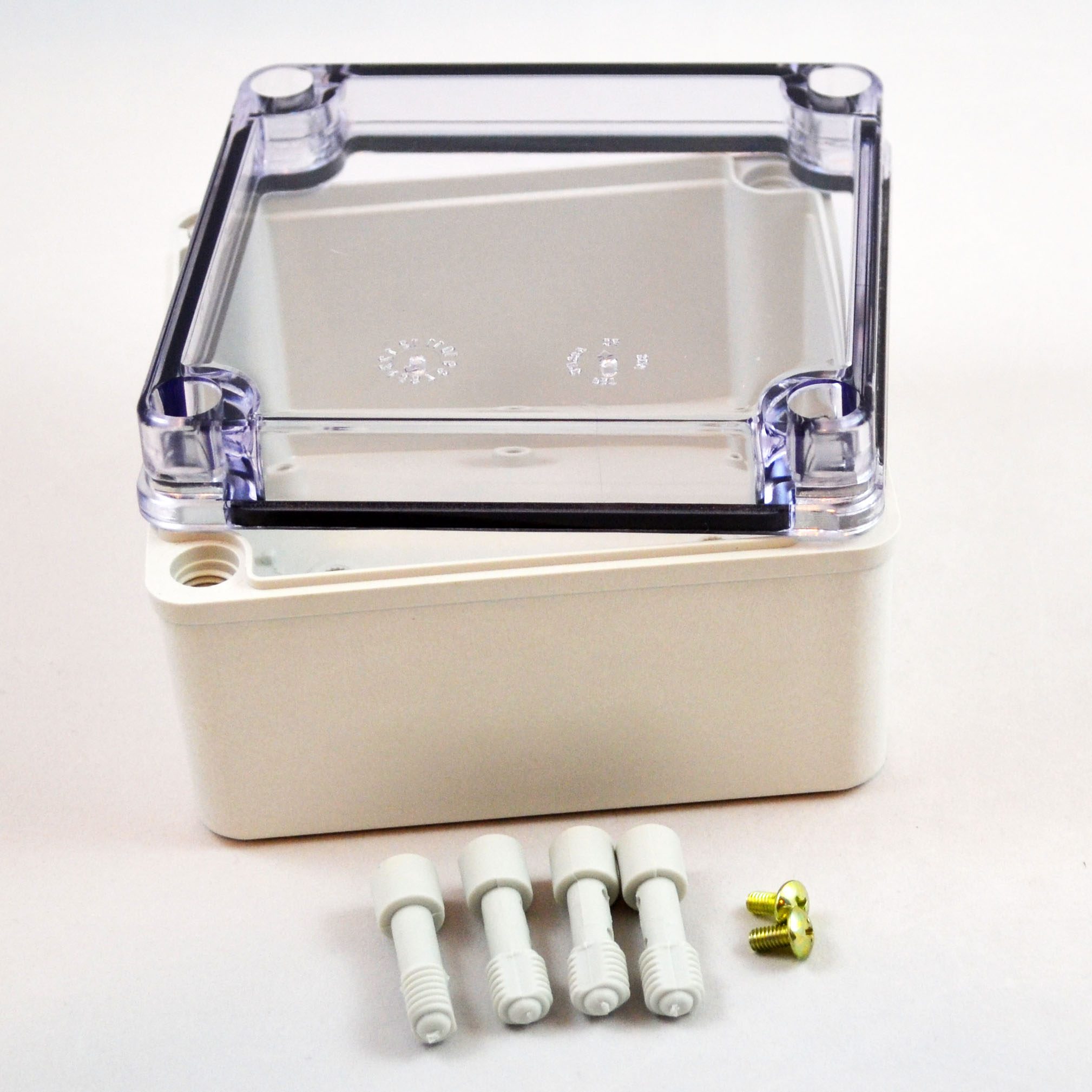

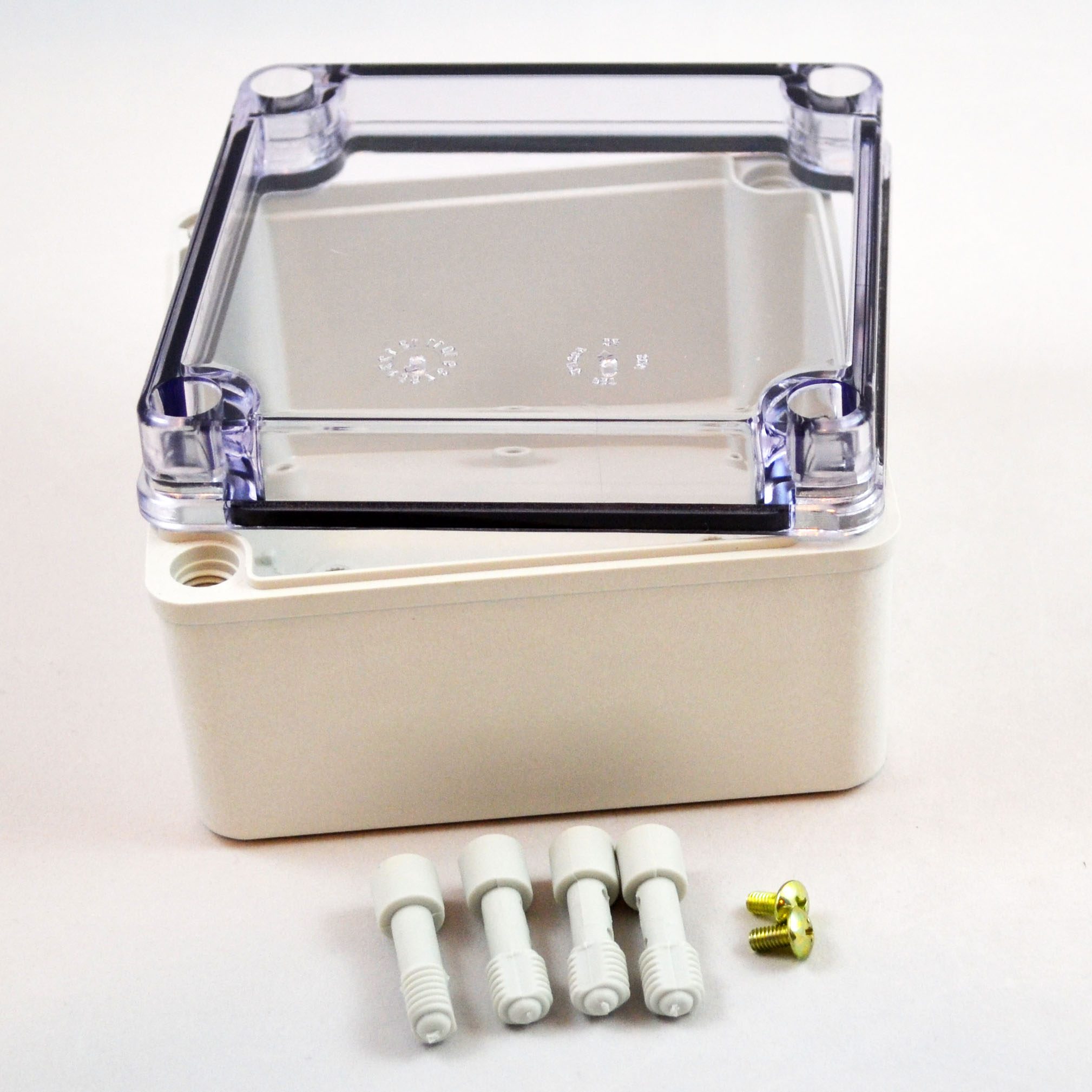

BUD’s PTS series is a low cost IP67 enclosure

2. Do you need to protect then entire enclosure, or only a sensitive component?

Size matters in protection. The smaller the item that needs to be protected, the less labor and gasketing goes into the protective enclosure. Therefore, a small die-cast type IP rated box can be selected to fit inside a larger piece of equipment if that is all that needs to be protected

3. What level of protection is required?

There is no point to specify extra protection such as UV stabilization if the enclosure is being used indoors. Often a lower level such as IP54 will work for your application. Each increasing level of protection can exponentially increase the cost.

4. What material do you actually need?

In the U.S., steel is often the choice for IP enclosures. However, plastic, the world wide standard, is less expensive and provides great protection in most applications. Steel makes sense only when using an extremely large enclosure or when the environment is extreme. Polycarbonate, fiberglass, and even die cast, all make low cost alternatives for the traditional steel enclosure.

5. Can the manufacturer assist you in making modifications to the enclosure?

If you are dealing with more than a few pieces, the vendor has the best equipment to insure that any hole locations, slots, or connector cut-outs are created with no damage to the enclosure. This saves significant money and time in obtaining a turn-key solution to your project

Often selecting the enclosure is a last minute rushed decision but by asking a few simple questions, the design of the proper enclosure can save significant money.