Bud Industries has a full offering of enclosures that meet UL certifications for NEMA 4x as well as NEMA 6 ratings. It is VERY important for a customer to understand what these certifications actually mean and why it is valuable to have these protections in place. Bud Industries takes safety very seriously and it is why we have many series of products that have UL certifications associated with them. By starting with a UL certified box it will be much less complicated to have your final design (with your internal components installed) certified allowing you to bring your product to market more quickly.

How UL Tests Enclosures for NEMA 4X and NEMA 6 Ratings

When it comes to industrial and commercial enclosures and boxes, durability and environmental protection are absolutely critical. UL (Underwriters Labs) certification for NEMA, (the National Electrical Manufacturers Association,) ratings like NEMA 4, NEMA 4X, NEMA 12, NEMA 13, NEMA 6, and NEMA 6P ensure that the enclosures meet rigorous standards to handle specific environmental encounters and physically protect your internal components from external issues. While we at the Bud team LOVES all of our water proof enclosures and we proudly display them at our homes and on our desks, we understand that the real purpose of our boxes is to protect components designed in for automation, electronic, and electrical applications. The real question is, how exactly does UL test these enclosures, and why is this testing so essential? We will explore its purpose with an overview of the detailed procedures behind UL testing for NEMA 4, NEMA 4X, and NEMA 6 ratings.

It is important to understand that customers have the capabilities to look up UL files by using the company name and UL file numbers that are visible on UL stickers.

Why UL Testing and Certifications for NEMA Ratings Matter

UL testing for NEMA ratings serves several key purposes for all designs. Here are some examples of why certification is necessary for many programs and applications.

- Guaranteeing Product Reliability: Customers count on enclosures to protect vital electrical, electronic, and mechanical components. UL certification provides confidence that the product will perform as needed in demanding conditions.

- Meeting Regulatory Standards: Many industries require compliance with NEMA standards for safety and operational efficiency. UL certification or certification from another 3rd party confirms that these standards are met. While not limited to this specific list of vertical markets, some key industries that often need these types of compliance ratings are industrial and manufacturing, oil and gas, utilities and power creation, alternative energy like solar power or wind energy, telecom, food processing, transportation, healthcare, construction, as well as agriculture.

- Building Market Trust: UL certification acts as a recognized mark of quality, boosting a product’s reputation and appeal in competitive markets including with customers who may not be familiar with the specific company or product.

- Enhancing Safety: Safety is important in all walks of life especially in the corporate or industrial world. Thorough testing by a 3rd party agency it minimizes risks like electrical failures, equipment damage, or hazardous situations caused by environmental exposure.

Understanding the value of UL certification is only half the story—let’s dive into the specific testing procedures for NEMA 4X and NEMA 6 enclosures.

Testing for NEMA 4X Certification

We have done many blogs regarding what a NEMA 4x enclosure commits to doing as we know it is a topic on the minds of many. Here are a few examples of these Blogs: NEMA 3 versus NEMA 4, Infographic on NEMA 4x Enclosure Rating is Best, and NEMA vs IP enclosures, the NEMA Rating Guide, or something a little more specific about Rating NEMA boxes versus IP boxes. Top level though, NEMA 4X enclosures are designed to protect against Water ingress from high pressure jets, dusty and debris, and corrosion in harsh environments. To secure a NEMA 4X rating, enclosures undergo the following three tests: Water Spray, Dust Ingress, and Corrosion Resistance which I will break down below.

- Water Spray Test: The goal of the Water Spray Test is to confirm that the enclosure can resist high-pressure water jets from any angle without water entering. A nozzle sprays water at 65 gallons per minute from a distance of 10-12 feet. The test lasts for a specified duration, focusing on seams, joints, and other potential weak points. No water should penetrate the enclosure in any way and compromise its interior. If water is detected, you can often use powder along the inside of the gasket to find out where water intrusion occurred.

- Dust Ingress Test: The purpose of the Dust Ingress test is to verify that the enclosure blocks airborne dust effectively. The enclosure is placed in a chamber filled with circulating dust particles for a set period. A vacuum may be used to simulate the pressure changes. The enclosure must remain dust-free during this entire process for it to pass.

- Corrosion Resistance Test: The focus of the Corrosion resistance test is to ensure the enclosure can withstand corrosive environments. The enclosure is exposed to a salt spray or a chemical environment for a defined period time, which would simulate prolonged exposure to corrosive agents like saltwater or industrial chemicals. For people who live near the water (Oceans, lakes, or gulfs,) this is really important. This test is looking to verify it does not rust. We often talk with customers about the need for corrosion resistant who live or work in these environments and the need to shift to something made out of plastic or stainless steel. Minimal corrosion and no structural degradation can occur to pass this test.

Waterproof Enclosure Testing for NEMA 6 Certification

NEMA 6 enclosures are built to protect against temporary submersion in water and ice formation on the exterior of the enclosure or box. The following tests (Submersion and are required for UL certification of NEMA 6 enclosures:

- Submersion Test: The goal of the Submersion Test is to verify the enclosure is watertight under temporary submersion. The enclosure is submerged in water at a specified depth (typically 6-10 feet) for at least 30 minutes. Think about the pressure that exists when something is under water for any period of time. The test parameters may vary depending on the application. No water can enter the enclosure during or after the submersion if it is to pass this test.

- External Ice Formation Test: The other test for NEMA 6 is the External Ice Formation Test which has a goal of confirming the enclosure’s integrity and functionality when ice forms on its surface. The enclosure is exposed to freezing conditions with moisture applied to encourage ice formation. These enclosures are then inspected for damage or performance issues. The enclosure must remain fully functional and undamaged to pass this test.

The UL Certification Process

Here’s an overview of how UL certifies enclosures for NEMA ratings:

- Initial Review: UL evaluates the enclosure’s design, materials, and specifications to ensure it meets baseline requirements for NEMA 4, NEMA 4X or NEMA 6 ratings.

- Laboratory Testing: The enclosure undergoes all required tests in a controlled UL-approved facility. Every step is documented in detail.

- Results Evaluation: UL inspectors analyze the results to confirm compliance with NEMA standards. Failures may require design modifications and retesting.

- Certification: Once testing is successfully completed, UL issues a certification mark that verifies compliance. This can be via a stamp or sticker.

- Ongoing Inspections: UL performs periodic follow-up checks to ensure the product continues to meet certification standards over time. UL inspectors will often visit facilities for every production run of UL certified boxes to verify they follow the processes that have been documented and meet the certifications.

Not Just NEMA 4x and 6

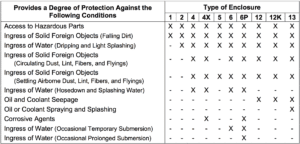

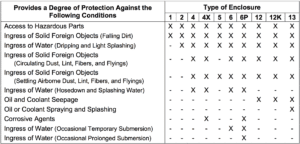

While this blog highlights NEMA 4x and NEMA 6 and NEMA 7P ratings as it covers most industrial applications that exist. Other NEMA ratings that are used can start at NEMA 1 which basically means you can’t stick your finger in it and it goes up from there. Here is a top level overview of the other NEMA ratings that are utilized on enclosures.

- NEMA 1: Indoor use, providing basic protection from dust.

- NEMA 3R: Outdoor use, protecting against rain, sleet, and snow.

- NEMA 4/4X: Protection against water, dust, and corrosion (4X adds chemical resistance to the enclosure).

- NEMA 6/6P: Protection against temporary and prolonged submersion. (6P provides significantly more resistance to prolonged underwater conditions.)

- NEMA 7: Use in hazardous locations with explosive gases.

- NEMA 12: Indoor use for protection against dust, oil, and dripping liquids.

Chart providing an overview of the NEMA ratings

Others companies and organizations can do this type of testing too…

UL testing is a great option for testing enclosures and equipment but there are other entities that do this as well and it differs by region of the world. In North America other key certifying bodies are CSA Group (Canadian Standards Association) in Canada, Intertek (ETL Listed), FM Approvals, and NSF International. There are options in Europe as well such as TÜV (Rheinland and SÜD) and a British company BSI Group (British Standards Institution). In Asia-Pacific there is SGS (Société Générale de Surveillance), KTL (Korean Testing Laboratory), and CCIC (China Certification & Inspection Group). You should be aware in certain regions they accept some of these, and and some areas of the world they do not. It is important to understand what your industry and country will accept as you go to market.

Water Proof UL Testing for NEMA Review

UL testing for NEMA 4X and NEMA 6 ratings is a meticulous process designed to ensure enclosures meet strict environmental protection standards. From high-pressure water spray tests to submersion and corrosion resistance evaluations, these procedures guarantee that certified enclosures will safeguard critical components in challenging environments.

Over 85% of Bud’s NEMA enclosures will either have UL or TUV ratings. The ones that do not are typically indoor rated ABS plastic enclosures that provide more indoor protection than protecting against the outside elements.

When choosing enclosures that need to protect against the elements, Bud’s enclosures with UL certification marks offer you the assurance that the product meets the industry’s highest standards for protection and performance.