How to Make a Waterproof Enclosure

The key to making an enclosure waterproof is a tight seal. For electrical enclosures having the highest level of water ingress protection, this is usually accomplished using a continuously poured silicone gasket and a tight-fitting cover. In other enclosures, water-tight gaskets may be made of other materials. Covers are secured with screws or with strong latches. Any possible gaps, such as in steel or stainless steel, enclosures must be fully sealed, usually by a seam weld. No gaps can exist.

Types of Waterproof Electrical Enclosures

There are many styles of waterproof electrical enclosures. Although our line is one of the largest in the industry, it may be helpful to see a few examples.

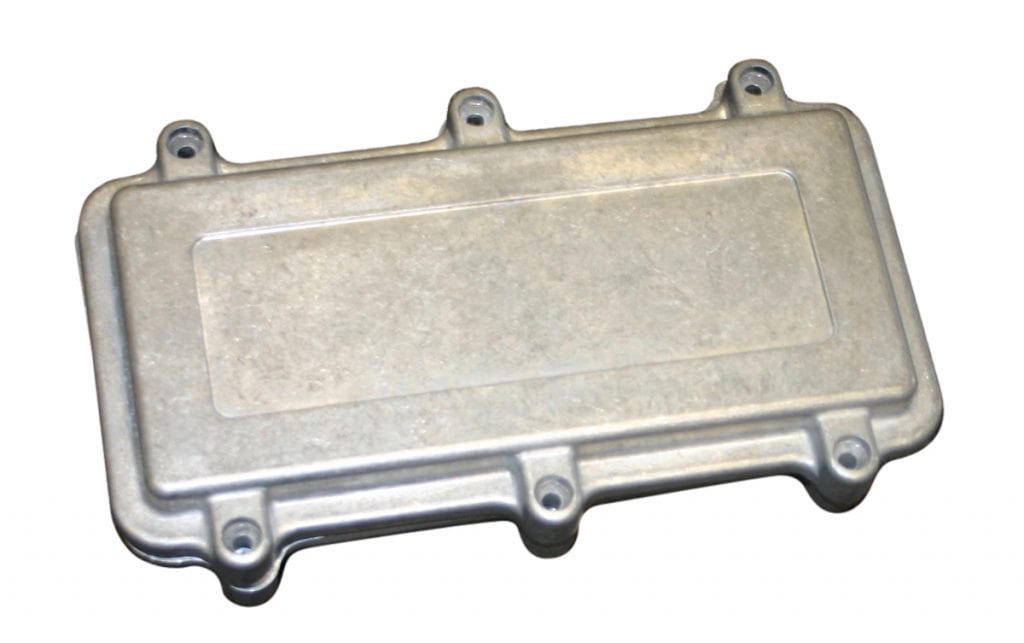

- One common choice is our AN-A Series NEMA box made of heat-absorbing die-cast aluminum. It is available with molded-in mounting flanges for easy installation to a wall or machine.

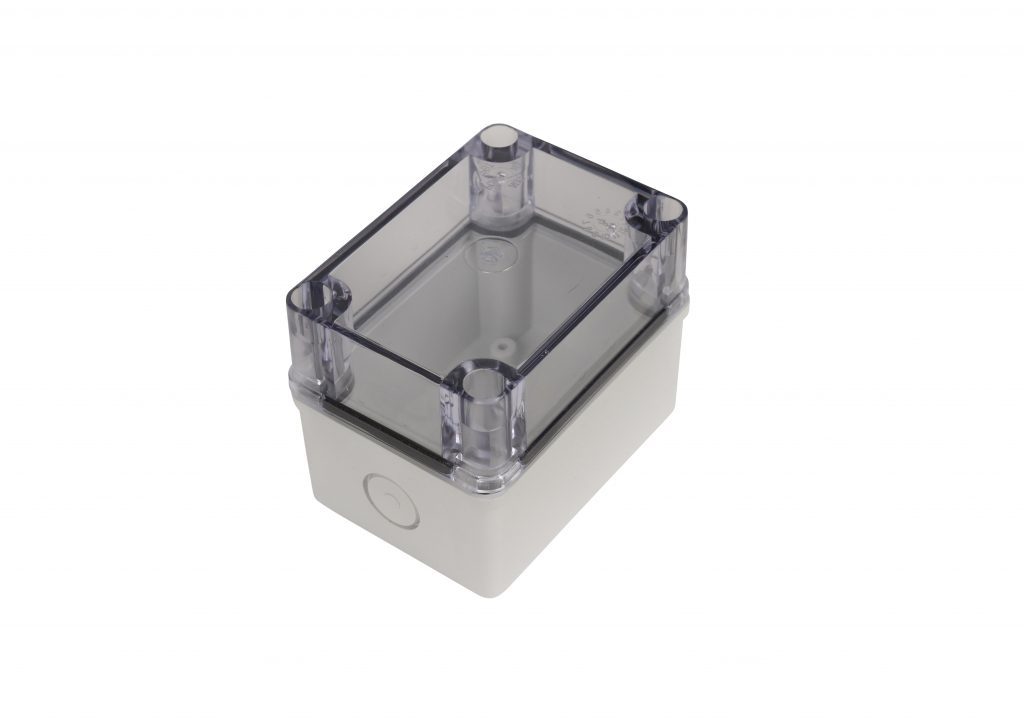

- Our NBB Series enclosure is a popular choice for a polycarbonate plastic box. It is available in a large range of sizes.

- Specialty enclosures include the DCH plastic box with two compartments ideal for separating electronics from power components or wiring. For DIN-rail mount applications, our DMX Series is an extruded aluminum enclosure able to withstand factory washdown.

- We offer a variety of fiberglass boxes, including polycarbonate plastic boxes reinforced with glass fibers. Some, such as the PTK Series, are available with clear plastic covers.

- When exceptional strength and security are required, we offer the

SNB Series stainless steel enclosure that is usually more affordable than competitor stainless steel enclosures. - For outdoor keypads and access control readers, our HD Series is a popular solution.

The list is seemingly endless. Browse our selection to find the perfect fit for your application.

Selecting for Wet Indoor and Weather Locations

How waterproof do you need? NEMA ratings and IP ratings define specific levels of protection against dust and water ingress. Our line includes weatherproof electrical enclosure protection all way up to NEMA 6P and IP68, which protects your design even when temporarily submerged in water.

Where will the enclosure be used? Plastic enclosures must be UV rated for outdoor applications. Indoor applications that will be washed down with hose-directed water require at least a NEMA 4X or IP65 rating.

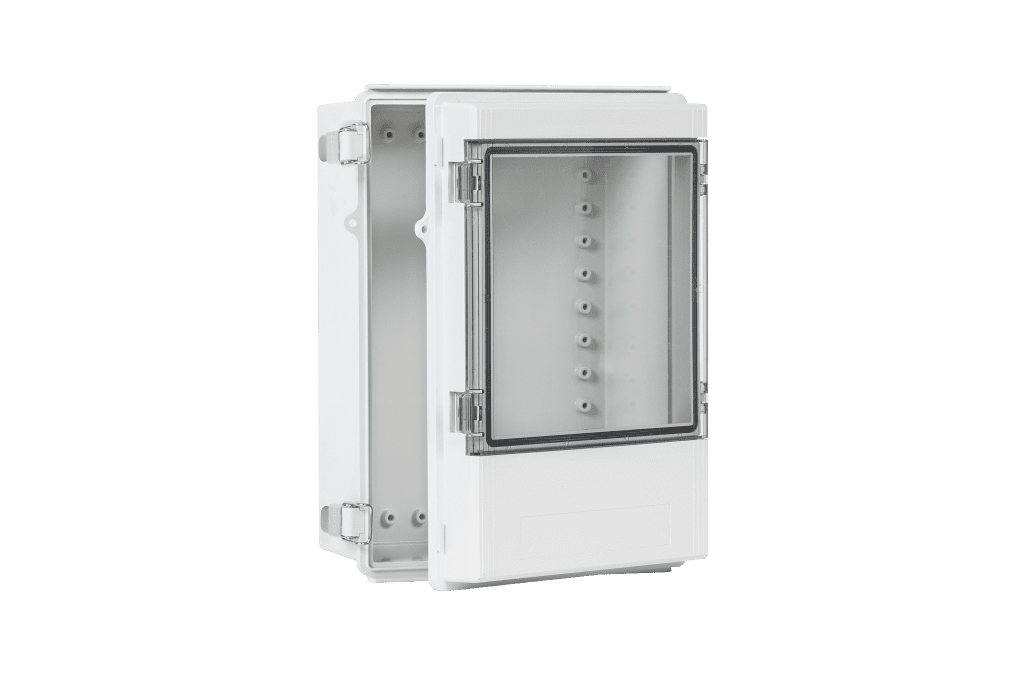

How will the enclosure be used? Considerations include how often the user will need access to the components inside the enclosure. A hinged enclosure will make access fast and convenient yet still completely secure.

Are there indicators or displays? A clear cover will allow users to see them without breaking the seal and exposing the enclosure contents to the elements.

Are appearances important? Metal enclosures are available with attractive finishes or with plain aluminum for a low-cost option.

Will the enclosure experience changes in air pressure? Changing weather can sometimes cause condensation to form internally or other issues. Bud offers an IP-rated vent that allows air to pass but blocks moisture. These and other vent accessories also allow heat to escape, meaning there is a weatherproof electrical enclosure solution for most environments.

Will you need to mount the enclosure? Most styles come with external mounting brackets, a few have mounting holes in the back, and some are designed for DIN-rail mounting.